hardness test procedure asme|rockwell hardness test formula : importer THE FIRST STATIC HARDNESS TESTING METHOD WAS INTRODUCED BY J. A. Brinell, a Swedish researcher, at the 1900 Paris World Exposition. A hardened steel ball or tungsten . web25 de ago. de 2023 · Gran Turismo: Directed by Neill Blomkamp. With David Harbour, Orlando Bloom, Archie Madekwe, Takehiro Hira. Based on the unbelievable, inspiring true story of a team of underdogs - a .

{plog:ftitle_list}

WEBJulia Puzzuoli. juliapuzzuoli. Instagram. Follow Discuss 🔥 UNDRESS AI. 🔥 UNDRESS AI. 108 Media. 60 Likes. Next Page .

rockwell hardness testing standards

Hardness testing of carbon steels are not defined in most construction Codes; it is addressed in API-582 and various NACE publications as a means to mitigate stress corrosion cracking. ASME Codes place the responsibility for corrosion related design on the .I've been a member since Jan 31, 2013 and have logged in 44 times. I last logged in .THE FIRST STATIC HARDNESS TESTING METHOD WAS INTRODUCED BY J. A. Brinell, a Swedish researcher, at the 1900 Paris World Exposition. A hardened steel ball or tungsten .

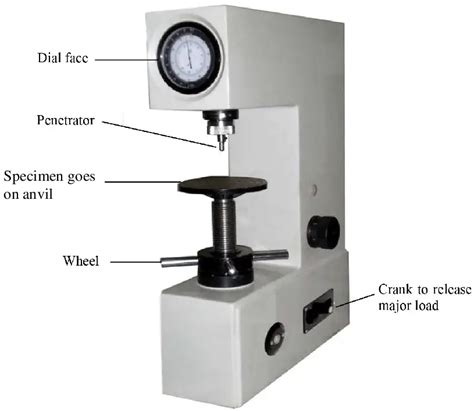

In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors . Listed below are common American Society for Testing and Materials (ASTM) .

Fogging Testing wholesalers

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. This .The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously .

The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the . ASTM E18 is the industry standard for Rockwell hardness testing of metallic materials. This specification includes both theory and standard practice statements. For those companies Nadcap accredited in heat treat where the .Hardness testing is required by ISO 15614 Pt1 for all ferritic steels with a specified minimum yield strength greater than 275MPa. A maximum hardness for joints in either the as-welded of PWHT’d condition is specified.

Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384). 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information . The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find .

This document outlines the procedure for hardness testing of production weldments in piping. It describes testing the hardness of all pipe joints using Brinell hardness testing on the base material, heat affected zone, and weld. Testing will be done according to the client's specification and acceptance criteria in ASME B31.3. Quality control personnel will perform and report the .

Standardization of Brinell Hardness Test Blocks Annex A4 1.3 This standard includes nonmandatory information in an appendix which relates to the Brinell hardness test: Table of Brinell Hardness Numbers Appendix X1 Examples of Procedures for Determining Brinell Hardness Uncertainty Appendix X2 1.4 At the time the Brinell hardness test was . Significance and Use 4.1 The rebound hardness method provides a means for rapid classification of the hardness of rock during site characterization for engineering, . (Withdrawn 2023) D5873-14 ASTM|D5873-14|en-US Standard Test Method for Determination of Rock Hardness by Rebound Hammer Method (Withdrawn 2023) . Standard Test Method for Leeb Hardness Testing of Steel Products A0956_A0956M-22 ASTM|A0956_A0956M-22 . Because of the variability of customs processes and procedures in different countries, ASTM International cannot guarantee transit times to international destinations. Customs duty and taxes are the responsibility of the consignee. Standard Test Method for Film Hardness by Pencil Test D3363-22 ASTM|D3363-22|en-US Standard Test Method for Film Hardness by Pencil Test Standard D3363 Standard Test Method for Film Hardness by Pencil Test> new BOS Vol. 06.01 Committee D01 $ 61.00 In stock Significance and Use.

Hardness testing is required by ISO 15614 Pt1 for all ferritic steels with a specified minimum yield strength greater than 275MPa. A maximum hardness for joints in either the as-welded of PWHT’d condition is specified. ASME IX does not require hardness testing. ASME IX allows a reduction in preheat of 55 O C before requalification is required . 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

This test method is an empirical test intended primarily for control purposes. No simple relationship exists between indentation hardness determined by this test method and any fundamental property of the material tested. For specification purposes, it is recommended that Test Method D785 be used for materials other than those described in 1.1. Abstract. Hardness is being assessed as a potential life-assessment tool for tracking microstructural degradation and remaining life in creep strength enhanced ferritic (CSEF) steels. Such methodology is already being utilized for the CSEF steel Grade 91, which has been widely implemented in both replacement parts and new construction over the last two .

rockwell hardness testing procedure

rockwell hardness testing advantages

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

Standards: DIN EN ISO 6506 / ASTM E10 Brinell Methods 2.2 Method Indenter Load F kg Load F N Load Factor 0.102 x F/D2 Hardness Range HBW* Material HBW 1/30 1 mm 30 kgf 294.2 N 30 95.5-653 . The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements,United States 1 E92−17 C1326 Test Method for Knoop Indentation Hardness of 3.1.4 Vickers hardness number, HV,n—the calculated result Advanced Ceramics from a Vickers hardness test, which is proportional to the test C1327 Test .THE FIRST STATIC HARDNESS TESTING METHOD WAS INTRODUCED BY J. A. Brinell, a Swedish researcher, at the 1900 Paris World Exposition. A hardened steel ball or tungsten carbide ball with a diameter (D) of 1, 2, 2.5, 5, or 10 mm was used as indenter. This was pressed into the smooth, clean specimen surface with a test force (F). Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics C1327-15R19 ASTM . By invoking this procedure, ASTM does not waive any of its rights to enforce this Agreement or to protect its intellectual property by any other means permitted by law. Licensee acknowledges and agrees that ASTM may imbed certain identifying or .

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information . As for the ASTM E10-23 standard, there is a heavy focus on the background of and actions taken throughout the Brinell hardness test procedure. This includes requirements and thorough detail on measuring the indentation, verifying the testing machines, converting to other hardness values, and preparing a test report.

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: . Engineers who want to learn more about Rockwell testing should read ASTM E18. Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike . Method PDF Available. LABORATORY MANUAL FOR HARDNESS TEST. . These heat-treated samples were then tested mechanically using the Brinell hardness test (BH). . Transactions of the ASME.

Rockwell Hardness Test: This method assesses the depth of indentation caused by a specific load on the material’s surface. It’s highly versatile and straightforward, making it widely used across industries. . Generally, the internationally accepted standards for hardness testing are those issued by ASTM (American Society for Testing . Significance and Use 4.1 The hardness of a material is a defined quantity having many scales and being dependent on the way the test is performed. In order to avoid the creation of a new method involving a new hardness scale, the UCI method converts into

This may include cylindrical parts which may require a correction as stated in Appendix A.6 of ASTM E18. If hardness conversion is used, procedures should address the conversion method as well as the requirements of paragraph 3.5.3 of AC7102/5, which requires that hardness test reports show both the measure value as well as the converted value. Significance and Use 4.1 The hardness of a material is a defined quantity having many scales and being dependent on the way the test is performed. In order to avoid the creation of a new method involving a new hardness scale, the UCI method converts into

test method are defined as surface roughness (that is, Ra = average roughness value, AA = arithmetic average). 3.1.5 verification—checking or testing the instrument to ensure conformance with this test method. 4. Summary of Test Method 4.1 During a hardness test, an impact body with a spheri-cally shaped tungsten carbide, silicon nitride .

Fogging Testing dealer

08/04/2019. Como descobrir uma traição? 4 sinais de que ela está te traindo. Foto: Reprodução. Relacionamento frio, desconfiança e mentiras são sinais de uma traição. .

hardness test procedure asme|rockwell hardness test formula